High Performance Insulation has pioneered innovative roofing technologies that transform deteriorating commercial roofs into durable, energy-efficient systems. As a result, these solutions deliver exceptional value and performance for building owners nationwide.

Why Spray Foam Roof Restoration Changes Everything

The evolution of foam restoration technology has revolutionized how building owners approach roof preservation. Moreover, rather than accepting premature replacement as inevitable, modern restoration provides cost-effective alternatives. In fact, these advanced solutions often exceed the performance of brand-new roofing systems.

Furthermore, these innovative methods address multiple challenges simultaneously. Building owners get improved waterproofing, enhanced insulation, better energy efficiency, and superior structural protection—all in one application.

Understanding which roofing systems benefit most requires comprehensive knowledge. Additionally, each commercial roof presents unique characteristics influenced by original construction methods, environmental exposure, and maintenance history. Therefore, professional assessment determines optimal strategies that maximize both immediate improvements and long-term performance.

7 Commercial Roof Types Perfect for Spray Foam Roof Restoration

1. Built-Up Roofs (BUR): Premier Restoration Candidates

Built-up roofs, commonly found on commercial buildings from the 1960s-1990s, respond exceptionally well to modern restoration applications. Consequently, these multi-layer asphalt and gravel systems often develop cracks, blisters, and deterioration over time.

Traditional tar and gravel construction faces challenges from thermal cycling, UV exposure, and moisture infiltration. However, modern foam technologies effectively overcome these issues.

Key Benefits for BUR Systems:

- Eliminates existing cracks and blisters

- Creates seamless, monolithic surfaces

- Adds significant insulation value (R-values of 6-7 per inch)

- Reduces roof surface temperatures by 50-60°F

Alt Text: Spray foam roof restoration application on built-up commercial roof system

Alt Text: Spray foam roof restoration application on built-up commercial roof system

Modified bitumen roofs also benefit tremendously from this approach. In addition, these systems develop predictable wear patterns at seams, flashings, and penetrations. Professional restoration creates continuous surfaces that eliminate vulnerable points while restoring waterproofing capabilities.

The restoration process begins with thorough surface preparation. First, this includes removal of loose gravel, repair of blisters, and reinforcement of damaged areas. Next, spray polyurethane foam fills irregularities and creates positive drainage. Finally, protective coatings provide weather resistance and reflective properties.

2. Metal Roof Systems: Essential Protection Applications

Aging metal roofs on warehouses, industrial facilities, and commercial buildings are prime restoration candidates. Furthermore, whether dealing with standing seam, corrugated, or R-panel metal roofing, foam applications provide superior protection.

Common Metal Roof Challenges:

- Thermal expansion and contraction

- Rust and corrosion at fasteners

- Fastener failure and leak points

- Condensation problems

Traditional repair methods often provide only temporary solutions. In contrast, comprehensive restoration encapsulates the entire metal surface. As a result, this approach eliminates thermal movement while providing superior insulation that reduces condensation problems common in metal buildings.

The process involves careful surface preparation including rust treatment, primer application, and repair of damaged panels. Additionally, foam thickness varies based on insulation requirements, typically ranging from 1 to 3 inches. The material adheres tenaciously to properly prepared surfaces, creating permanent bonds that strengthen the overall system.

3. Single-Ply Membrane Roofs: Critical Timing Matters

EPDM (rubber), TPO, and PVC membrane roofs installed 10-20 years ago often show signs of deterioration. Moreover, weathering, shrinkage, and seam failure commonly occur during this timeframe. Therefore, timely restoration is crucial for extending roof life.

Spray-applied systems rejuvenate these surfaces effectively. Furthermore, the application creates a monolithic surface that eliminates vulnerable seams and can extend roof life by 10-20 years.

EPDM Transformation: EPDM roofs, known for their black color and heat absorption, benefit tremendously from restoration. Specifically, white or light-colored coatings transform them into cool roofing systems. This color change alone can reduce cooling costs by 20-40% in warm climates.

TPO and PVC Renewal: These membranes lose plasticizers over time, becoming brittle and prone to cracking. However, restoration restores flexibility while adding protective layers that prevent further degradation.

Alt Text: Commercial EPDM roof after spray foam roof restoration with reflective coating

Alt Text: Commercial EPDM roof after spray foam roof restoration with reflective coating

Compatibility between existing membranes and restoration products requires careful consideration. Nevertheless, professional contractors perform adhesion tests to ensure proper bonding. Specialized primers and preparation techniques ensure long-lasting adhesion that prevents delamination.

4. Concrete and Structural Decks: Comprehensive Solutions

Commercial buildings with concrete roof decks benefit significantly from foam insulation and protective coatings. In particular, these applications address common issues including thermal bridging, water infiltration, and structural movement cracks.

Concrete decks present unique challenges:

- High thermal mass

- Moisture retention issues

- Alkalinity affecting coating adhesion

- Structural movement and settling

The spray-applied systems create continuous insulation layers that improve building envelope performance. Additionally, they provide long-term waterproofing protection. Furthermore, the closed-cell structure prevents water infiltration while allowing controlled vapor permeation.

Structural deck variations—including precast concrete, lightweight insulating concrete, and gypsum decks—each require specific preparation techniques. Consequently, surface profiling, crack repair, and moisture mitigation ensure successful applications. Moreover, the lightweight nature adds minimal dead load to structures.

Advanced Restoration Technologies

5. SPF Systems: The Gold Standard

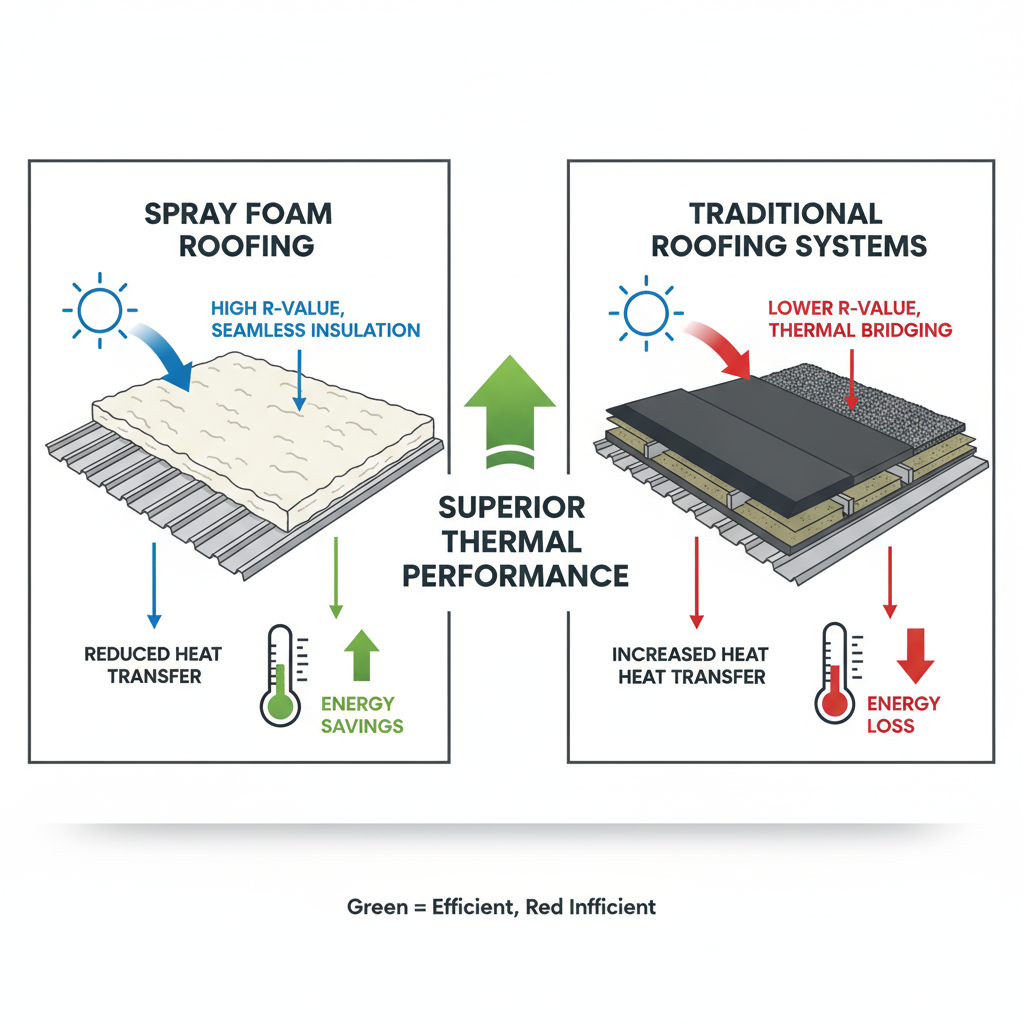

Spray polyurethane foam (SPF) roofing delivers unmatched insulation value. Specifically, with R-values exceeding traditional roofing materials, SPF provides exceptional thermal performance. This closed-cell foam adheres directly to existing substrates, creating seamless, self-flashing protection.

Performance Advantages:

- Superior insulation (R-6 to R-7 per inch)

- Lightweight application ideal for load restrictions

- HVAC cost reductions up to 30%

- Seamless protection around penetrations

The chemistry of modern SPF has evolved significantly. As a result, today’s formulations are optimized for specific climate conditions and application requirements. High-density foams provide exceptional compressive strength for high-traffic areas. Meanwhile, standard densities offer optimal insulation value for typical applications.

Professional installation requires sophisticated equipment and experienced technicians. Indeed, they must understand the critical relationship between temperature, humidity, and foam quality. Proper proportioning, mixing, and application temperatures ensure optimal foam structure with consistent cell formation.

The self-adhering nature eliminates the need for mechanical fasteners or adhesives. Consequently, this reduces installation time while eliminating potential leak points. Moreover, the foam’s ability to conform to irregular surfaces provides excellent air sealing benefits.

6. Elastomeric and Silicone Coating Systems

Modern elastomeric and silicone coatings provide weather-resistant barriers that reflect up to 90% of UV radiation. Furthermore, these spray-applied systems expand and contract with temperature changes, maintaining flexibility throughout extreme weather conditions.

Coating Selection Guide:

Silicone Coatings:

- Superior ponding water resistance

- Maintains flexibility at temperature extremes

- Hydrophobic nature prevents water absorption

- Ideal for challenging applications

Acrylic Elastomeric Coatings:

- Excellent adhesion to various substrates

- Superior dirt pickup resistance

- Maintains reflectivity over time

- Low VOC content and environmental advantages

Urethane Coatings:

- Exceptional abrasion resistance

- Chemical resistance for industrial applications

- Withstands foot traffic and equipment movement

- Color stability with aliphatic formulations

Alt Text: Comparison of elastomeric and silicone coatings for roof restoration projects

Alt Text: Comparison of elastomeric and silicone coatings for roof restoration projects

Multiple coat applications build thickness gradually. Thus, this ensures complete coverage while maintaining uniform appearance. Additionally, water-based systems offer ease of application and environmental benefits.

7. Specialized Coatings: Advanced Options

Innovative coating formulations address specific challenges in commercial roofing projects. As a result, these advanced products ensure year-round application possibilities and optimal performance in diverse climates.

Ceramic-Enhanced Coatings: These incorporate microscopic ceramic beads that provide additional insulation value while maintaining flexibility. Moreover, the advanced formulations reduce thermal conductivity while providing superior weathering resistance. In addition, ceramic content improves impact resistance and extends coating life.

Fire-Resistant Coatings: These meet strict building code requirements for flame spread and smoke development. Furthermore, specialized formulations provide Class A fire ratings while maintaining waterproofing performance. Some feature intumescent properties that provide additional protection by expanding when exposed to high temperatures.

Aluminum-Pigmented Coatings: These provide enhanced UV protection and heat reflection. Particularly, they’re effective in hot climates where maximum solar reflectance is critical.

The Professional Restoration Process

Initial Evaluation and Assessment

Professional evaluation begins with comprehensive documentation of existing conditions. Specifically, this includes visual inspection, core sampling, and moisture detection. Moreover, infrared thermography identifies moisture infiltration that requires remediation before application.

Structural evaluation ensures adequate load capacity for additional materials. Additionally, it identifies any repairs required before restoration begins. Furthermore, drainage assessment determines whether installation should include tapered insulation systems.

Existing drainage patterns, scupper locations, and roof penetrations all influence application strategies. Therefore, professional contractors develop detailed specifications addressing all identified issues.

Learn more about commercial roofing inspection standards from the National Roofing Contractors Association.

Surface Preparation: The Foundation of Success

Successful applications require meticulous surface preparation. As a result, this ensures proper adhesion and long-term performance. Power washing removes dirt, debris, and loose materials that could compromise adhesion.

Critical Preparation Steps:

- Thorough cleaning and debris removal

- Primer application for chemical bonds

- Repair of existing defects (holes, damage, deteriorated insulation)

- Wet insulation removal and replacement

- Fastener tightening or replacement

Each step is essential for optimal results. Consequently, skipping preparation steps often leads to premature failure. Moreover, proper preparation accounts for up to 50% of project success.

Application Techniques and Quality Control

Professional application requires sophisticated equipment operated by trained technicians. Specifically, plural-component proportioning equipment ensures accurate mixing of foam components. Heated hoses maintain optimal material temperatures throughout the application process.

Quality control measures include:

- Wet film thickness measurements

- Foam rise observations

- Surface temperature monitoring

- Environmental condition documentation

Environmental conditions significantly influence application techniques. Indeed, wind speed, humidity, and temperature may require protective enclosures or scheduling adjustments. Therefore, experienced contractors monitor conditions closely and adjust accordingly.

Alt Text: Professional spray foam roof restoration application process on commercial building

Alt Text: Professional spray foam roof restoration application process on commercial building

Key Benefits of Professional Restoration

Environmental Sustainability

Foam restoration significantly reduces landfill waste by eliminating tear-off requirements. Moreover, cool roof coatings can reduce surface temperatures by 50-60°F, decreasing urban heat island effects. These sustainable solutions align with LEED certification requirements and corporate environmental initiatives.

Life cycle assessments demonstrate clear environmental advantages versus replacement. Specifically, avoided landfill disposal, reduced transportation emissions, and decreased manufacturing impacts provide measurable benefits. Furthermore, energy savings throughout the extended roof life reduce carbon footprints considerably.

According to the U.S. Department of Energy, cool roofing systems can significantly reduce building energy consumption in commercial applications.

Cost-Effective Asset Management

Restoration typically costs 50-70% less than complete replacement while delivering comparable performance. Furthermore, the installation process minimizes business disruption. Projects often complete without relocating occupants or interrupting operations.

Financial Advantages:

- Extended roof life defers capital expenditures

- Maximizes return on roofing investments

- Reduces installation time and labor costs

- Eliminates disposal expenses

- Potential energy efficiency incentives

- Accelerated depreciation schedules

Financial analysis comparing restoration versus replacement demonstrates compelling economic advantages. Moreover, reduced installation time decreases labor costs while minimizing overhead expenses. As a result, building owners see ROI within 3-5 years typically.

Enhanced Building Performance

Professional applications improve overall building performance through multiple mechanisms. Specifically, superior waterproofing, increased insulation values, and reduced thermal movement all contribute. These improvements translate to more comfortable interior environments and reduced HVAC strain.

Indoor Environmental Quality Improvements:

- Reduced temperature fluctuations

- Decreased drafts and air infiltration

- Improved humidity control

- Enhanced sound attenuation

- Reduced exterior noise transmission

The seamless nature eliminates common failure points, reducing maintenance requirements and emergency repair calls. Furthermore, improved building envelope performance reduces HVAC cycling, extending equipment life significantly.

Explore our related guide on commercial roof maintenance best practices for more information.

Long-Term Maintenance Requirements

Preventive Maintenance Protocols

Successful systems require regular maintenance to achieve maximum service life. Importantly, annual inspections identify minor issues before they become major problems. Semi-annual cleaning maintains coating reflectivity and drainage performance.

Essential Maintenance Activities:

- Visual inspections for coating wear

- Foam damage assessment

- Drainage system checks

- Touch-up coating applications

- Debris removal from drains and scuppers

- Documentation of maintenance activities

Regular maintenance investments typically return 5-10 times their cost through extended roof life and avoided repairs. Therefore, proactive maintenance is one of the most cost-effective investments building owners can make.

Performance Monitoring

Modern technology enables sophisticated monitoring through sensors, thermal imaging, and data analytics. Specifically, temperature sensors document insulation performance and identify degradation requiring attention. Moreover, moisture monitoring systems provide early warning of leaks before interior damage occurs.

Performance data supports warranty claims while optimizing maintenance schedules. Rather than following arbitrary timelines, monitoring enables condition-based maintenance strategies.

According to the National Roofing Contractors Association, proper maintenance and monitoring significantly extend the life of restored roofing systems. Consequently, this makes professional restoration an excellent long-term investment for commercial properties.

Learn about roof warranty requirements and maintenance schedules to protect your investment.

The High Performance Insulation Advantage

With over four decades of experience in commercial roofing technology, High Performance Insulation brings unparalleled expertise to every project. Furthermore, our certified applicators utilize cutting-edge equipment and premium materials to deliver solutions that exceed industry standards.

We understand that each commercial roof presents unique challenges. Consequently, our customized approach ensures optimal results for every application. Our commitment to quality, innovation, and reliability means property owners and facility managers can trust their investments to proven professionals.

Our Differentiators:

- Manufacturer certifications for premium warranty programs

- Ongoing training in latest application techniques

- Exceptional safety record protecting workers and occupants

- Responsive customer service throughout project lifecycle

- Sustainable solutions supporting environmental conservation

We combine technical expertise with responsive customer service. As a result, this ensures projects progress smoothly from initial assessment through final inspection.

Alt Text: Professional roofing team installing spray foam roof restoration system

Alt Text: Professional roofing team installing spray foam roof restoration system

Making the Right Decision

Determining whether restoration suits your roofing needs requires careful consideration of multiple factors. Specifically, building age, current roof condition, energy costs, and capital budgets all influence the decision.

Professional consultation provides objective assessments that support informed decision-making. Furthermore, these evaluations are based on technical merit and economic analysis rather than sales pressure.

High Performance Insulation’s systematic approach evaluates all relevant factors before recommending strategies. Our detailed proposals include:

- Comprehensive cost-benefit analyses

- Energy savings projections

- Multiple warranty options

- References from similar projects

- Expected performance outcomes

We provide references from similar projects, demonstrating successful outcomes that validate our recommendations. As a result, this transparency helps executives make confident decisions about their roofing investments.

Conclusion: Smart Asset Management for Your Commercial Roof

Spray foam roof restoration for aging commercial roofs represents intelligent asset management. Indeed, it delivers both immediate and long-term benefits for building owners. From enhanced energy efficiency to extended roof life, these innovative solutions protect buildings while reducing operational costs.

The evolution of spray technology continues to expand possibilities for roofs previously considered replacement candidates. Moreover, advanced materials, improved application techniques, and comprehensive warranty programs make restoration increasingly attractive. Building owners now have sustainable, cost-effective alternatives to expensive replacements.

High Performance Insulation’s dedication to excellence ensures every project meets the highest standards of quality and performance. Furthermore, our proven track record demonstrates our commitment to client success.

Ready to Transform Your Commercial Roof?

Contact our roofing specialists today to discover how professional restoration can transform your commercial roof into a high-performance asset. Our experienced team stands ready to evaluate your needs and develop customized solutions that deliver exceptional value while supporting your sustainability goals.

Let us show you how the right restoration approach can protect your building and bottom line for decades to come. Call us today for a free consultation and roof assessment. Please check out our site for all of your spary foam needs click here

Latest Roofing Insights

Spray Foam Commercial Roofing: Top 7 Reasons to Choose It in 2025

Discover the top 7 reasons to choose spray foam commercial roofing in 2025. Energy savings,

Spray Foam Commercial Roofing: Top 5 Proven Benefits for 2025

Discover spray foam commercial roofing benefits: 30-50% energy savings, 30+ year lifespan, seamless waterproofing, and

Spray Foam Roof Restoration: The 2025 Property Manager’s Guide

Save 50-75% vs. a full roof replacement! Learn how spray foam roof restoration extends roof