# Spray Foam Commercial Roofing: Top 7 Reasons to Choose It in 2025

Commercial building owners face a critical decision when selecting a roofing system. Your roof protects your entire investment, affects energy costs, and impacts long-term maintenance budgets. However, spray foam commercial roofing has emerged as a leading solution for businesses seeking superior performance and value. Moreover, this innovative roofing technology offers benefits that traditional materials simply cannot match. In this comprehensive guide, we’ll explore the top seven reasons why spray foam commercial roofing continues to gain popularity among property owners nationwide. Therefore, you’ll understand exactly why this roofing solution might be the perfect choice for your building.

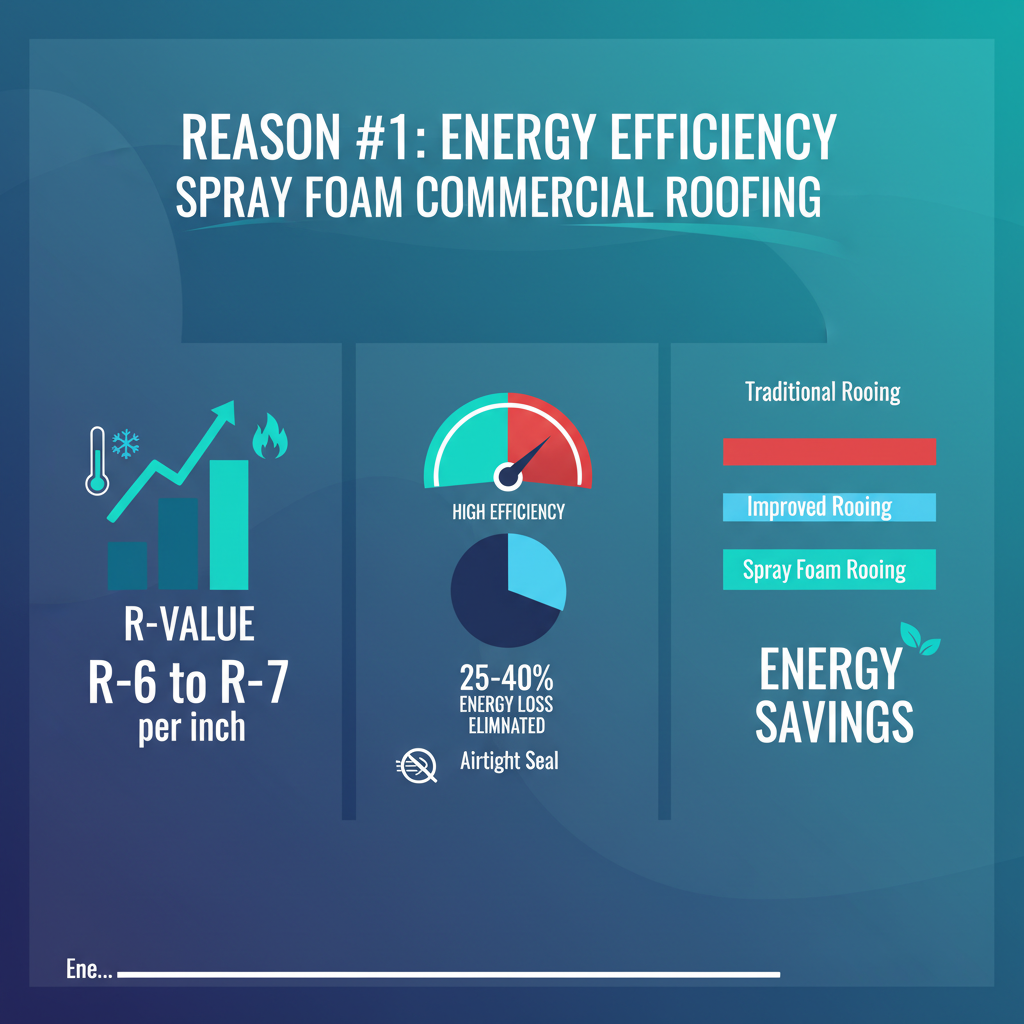

## Reason #1: Spray Foam Commercial Roofing Delivers Unmatched Energy Efficiency

Energy costs represent one of the largest operating expenses for commercial buildings. However, spray foam commercial roofing provides exceptional thermal protection that dramatically reduces these costs. Furthermore, the superior insulation properties of spray polyurethane foam create substantial savings that justify the initial investment.

### Superior R-Value Performance

Spray foam commercial roofing delivers an impressive R-value of R-6 to R-7 per inch of thickness. In contrast, traditional insulation materials provide significantly lower thermal resistance. For instance, fiberglass batting only achieves R-3 to R-4 per inch. Additionally, spray foam maintains its R-value over time, unlike materials that settle or degrade.

The U.S. Department of Energy recognizes spray polyurethane foam as one of the most efficient insulation materials available. Moreover, this efficiency translates directly to reduced HVAC costs. Commercial buildings typically see energy savings of 30% to 50% after installing spray foam commercial roofing systems.

### Seamless Air Barrier Technology

Beyond thermal resistance, spray foam commercial roofing creates an airtight seal across the entire roof surface. Therefore, it eliminates air leakage that accounts for 25% to 40% of energy loss in typical buildings. Furthermore, the monolithic application means no seams, gaps, or fastener penetrations that allow conditioned air to escape.

This complete air sealing capability sets spray foam apart from traditional roofing systems. Additionally, the foam conforms perfectly to roof penetrations, HVAC units, and irregular surfaces. As a result, you get consistent insulation performance without thermal bridging or weak spots. Consequently, your building maintains comfortable temperatures more efficiently throughout the year.

## Reason #2: Long Lifespan Makes Spray Foam Commercial Roofing Cost-Effective

Initial cost concerns often dominate roofing decisions. However, spray foam commercial roofing delivers exceptional value through its remarkable longevity. Moreover, when properly maintained, these systems can last 50 years or more—significantly outlasting traditional roofing materials.

### Durability That Outlasts Alternatives

Traditional commercial roofing materials typically require replacement every 15-25 years. In contrast, spray foam commercial roofing systems routinely exceed 30 years before needing major work. Furthermore, many properly maintained spray foam roofs continue performing effectively for 50+ years. Therefore, building owners avoid costly tear-off and replacement expenses that plague conventional roofing.

The seamless, monolithic nature of spray foam eliminates common failure points. Additionally, there are no seams to split, no fasteners to back out, and no membranes to shrink. As a result, the most common causes of roof failure simply don’t apply to spray foam commercial roofing systems. Moreover, the foam’s rigid structure resists wind uplift forces that can damage other roofing types.

### Renewable Coating System

The protective coating applied over spray foam requires periodic renewal every 10-20 years. However, this simple recoating process extends the roof’s life indefinitely at a fraction of replacement cost. Furthermore, recoating typically costs $1-2 per square foot compared to $4-10 for complete roof replacement.

This renewable approach means spray foam commercial roofing can literally last the lifetime of your building. Additionally, each recoating restores the system’s appearance and protective capabilities. Therefore, you avoid the waste and expense associated with tear-off and disposal of failed roofing materials. Consequently, spray foam represents both an economical and environmentally responsible roofing choice.

## Reason #3: Spray Foam Commercial Roofing Prevents Leaks and Water Damage

Water infiltration represents the number one concern for commercial property owners. However, spray foam commercial roofing provides superior leak prevention compared to traditional systems. Moreover, the seamless application creates a monolithic barrier that water simply cannot penetrate when properly installed.

### No Seams Means No Leaks

Traditional roofing systems rely on seams, overlaps, and fasteners that create thousands of potential leak points. In contrast, spray foam commercial roofing forms a continuous membrane across the entire roof surface. Therefore, there are no seams to fail, no laps to separate, and no fastener holes to leak. Additionally, the foam’s expansive nature ensures complete coverage around all penetrations.

The Spray Polyurethane Foam Alliance reports that properly installed spray foam roofing systems provide virtually leak-proof performance. Furthermore, the self-flashing characteristics mean the foam conforms perfectly to roof details, creating watertight seals. As a result, building owners enjoy peace of mind knowing their contents and structure are protected from water damage.

### Self-Healing Properties

Minor impacts or damage to spray foam commercial roofing systems can be easily repaired without replacing entire sections. Moreover, the foam material allows for seamless patching that restores waterproofing integrity. Additionally, repairs blend invisibly with the existing foam, maintaining both appearance and performance.

This repairability extends the system’s effective life even further. Furthermore, addressing small problems prevents them from becoming major failures. Therefore, proactive maintenance keeps your spray foam commercial roofing performing optimally for decades. Consequently, you avoid the catastrophic leaks and emergency repairs that plague traditional roofing materials.

## Reason #4: Lightweight Design Reduces Structural Load

Many commercial buildings, particularly older structures, have limited structural capacity for heavy roofing materials. However, spray foam commercial roofing provides an ideal solution with its exceptionally light weight. Moreover, this characteristic makes spray foam perfect for re-roofing projects where adding weight is a concern.

### Minimal Weight Addition

Spray foam commercial roofing weighs approximately 50-60 pounds per 100 square feet for a typical 2-inch application. In comparison, built-up roofing can weigh 500-700 pounds per 100 square feet. Additionally, concrete tile roofing exceeds 900 pounds per 100 square feet. Therefore, spray foam adds minimal load to the building structure.

This lightweight nature offers multiple advantages. For instance, it allows re-roofing without removing existing materials in many cases. Furthermore, it enables roofing upgrades on structures that cannot support heavier systems. As a result, building owners gain modern roofing performance without costly structural reinforcement. Additionally, the reduced weight means less stress on aging building components.

### Ideal for Restoration Projects

When re-roofing is necessary, spray foam commercial roofing can often be applied directly over existing materials. Therefore, you eliminate the expense of tear-off, disposal, and disruption to building operations. Moreover, this restoration approach is significantly faster than traditional roof replacement. Consequently, your building remains operational throughout the roofing project.

The ability to restore rather than replace saves both money and time. Additionally, keeping existing materials out of landfills aligns with sustainability goals. Furthermore, spray foam commercial roofing restoration typically costs 40-60% less than complete replacement. As a result, building owners achieve modern roofing performance while maximizing budget efficiency.

## Reason #5: Spray Foam Commercial Roofing Adapts to Complex Roof Designs

Commercial buildings often feature complex roof configurations with multiple levels, penetrations, and transitions. However, spray foam commercial roofing handles these challenges effortlessly. Moreover, the liquid application allows complete coverage regardless of roof complexity or geometry.

### Perfect for Irregular Surfaces

Traditional roofing materials struggle with complex roof designs. In contrast, spray foam commercial roofing conforms perfectly to any surface shape or configuration. Furthermore, the foam flows around obstacles, fills gaps, and creates seamless transitions between different roof levels. Therefore, even the most challenging roof designs receive complete coverage and protection.

This adaptability eliminates the detail work and custom fabrication required with other roofing systems. Additionally, spray foam naturally creates proper drainage slopes on flat roofs, preventing ponding water. Moreover, the foam’s self-leveling properties ensure even thickness across the entire roof surface. As a result, you get consistent performance regardless of roof complexity.

### Comprehensive Penetration Sealing

Commercial roofs typically contain numerous penetrations for HVAC equipment, skylights, vents, and other components. However, spray foam commercial roofing seals around all these elements perfectly. Moreover, the foam’s expansive nature ensures complete contact and adhesion to vertical surfaces. Therefore, traditional problem areas like pipe flashings become non-issues with spray foam.

The National Roofing Contractors Association identifies penetrations as common leak sources in traditional roofing. Furthermore, proper detailing around penetrations requires significant labor with conventional materials. In contrast, spray foam commercial roofing automatically creates watertight seals during application. Consequently, installation time decreases while reliability increases.

## Reason #6: Spray Foam Commercial Roofing Environmental Benefits Support Sustainability Goals

Modern businesses increasingly prioritize environmental responsibility. However, spray foam commercial roofing aligns perfectly with sustainability initiatives. Furthermore, these environmental benefits make spray foam an attractive choice. Moreover, the system’s environmental benefits extend beyond energy efficiency to encompass lifecycle impacts and resource conservation.

### Reduced Carbon Footprint

The exceptional energy efficiency of spray foam commercial roofing directly reduces your building’s carbon footprint. Furthermore, lower energy consumption means decreased power plant emissions. According to the Environmental Protection Agency, improving building insulation ranks among the most effective carbon reduction strategies.

Additionally, the long lifespan of spray foam systems reduces embodied carbon. Therefore, manufacturing and transportation impacts are amortized over 50+ years instead of 15-20 years. Moreover, the restoration capability means avoiding tear-off and disposal of failed roofing materials. As a result, spray foam commercial roofing generates significantly less construction waste than traditional systems.

### Resource Conservation

The ability to restore existing roofs with spray foam prevents millions of tons of roofing waste annually. Furthermore, keeping old roofing materials out of landfills conserves both space and resources. Additionally, spray foam application requires no water, unlike many roofing processes that consume significant quantities.

Modern spray foam formulations increasingly use recycled materials and environmentally responsible blowing agents. Moreover, industry leaders continue developing products with lower global warming potential. Therefore, spray foam commercial roofing technology keeps improving its environmental profile. Consequently, choosing spray foam supports your organization’s sustainability commitments while delivering superior performance.

## Reason #7: Spray Foam Commercial Roofing Provides Superior Wind and Weather Resistance

Commercial buildings in harsh climates need roofing systems that withstand extreme weather conditions. However, spray foam commercial roofing provides exceptional wind and weather resistance. Furthermore, the rigid foam structure and complete adhesion create remarkable durability. Moreover, this weather resistance protects your investment for decades.

### Hurricane-Resistant Performance

Spray foam commercial roofing adheres directly to the roof substrate, creating a unified structure. Therefore, wind cannot get underneath to cause uplift and blow-off. Furthermore, the monolithic nature eliminates seams and fasteners that high winds can exploit. Additionally, properly installed spray foam roofing systems routinely withstand hurricane-force winds exceeding 120 mph.

Testing by industry organizations demonstrates superior wind resistance compared to traditional roofing. Moreover, spray foam’s rigid structure resists membrane fluttering that causes fatigue and failure. As a result, buildings in hurricane-prone regions benefit from enhanced protection. Consequently, many property owners in coastal areas specifically choose spray foam commercial roofing for its storm resistance.

### Hail and Impact Resistance

The protective coating applied over spray foam provides impact resistance that shields the foam from hail damage. Furthermore, even if damage occurs, repairs are straightforward and restore full performance. Additionally, the foam’s cushioning effect absorbs impact energy that would puncture thinner roofing membranes.

Regular maintenance inspections catch any weather-related damage early. Moreover, small issues are easily addressed before they compromise the system. Therefore, spray foam commercial roofing maintains its protective capabilities through years of exposure to harsh conditions. Consequently, building owners enjoy reliable protection regardless of climate challenges.

## Making the Decision: Is Spray Foam Commercial Roofing Right for Your Building?

The seven compelling reasons outlined above demonstrate why spray foam commercial roofing continues gaining market share. However, making the right decision for your specific building requires careful consideration. Moreover, working with qualified contractors ensures you achieve the full benefits these systems offer.

### Evaluating Your Building’s Needs

Consider your building’s specific requirements when evaluating roofing options. For instance, buildings with high energy costs benefit tremendously from spray foam’s superior insulation. Additionally, structures with complex roof designs appreciate the adaptability of liquid-applied systems. Furthermore, older buildings with limited structural capacity find spray foam’s lightweight nature ideal.

The decision should account for total lifecycle costs rather than just initial investment. Moreover, factor in energy savings, extended lifespan, and reduced maintenance when comparing options. Therefore, spray foam commercial roofing often represents the most economical choice despite higher upfront costs. Consequently, savvy building owners increasingly recognize the long-term value these systems provide.

### Finding Qualified Contractors

Success with spray foam commercial roofing depends heavily on proper installation. Therefore, selecting experienced, certified contractors is absolutely essential. Furthermore, look for contractors with Spray Polyurethane Foam Alliance certification. Additionally, request references from recent commercial projects and verify insurance coverage.

Quality contractors conduct thorough pre-installation assessments. Moreover, they provide detailed specifications and warranties backing their work. Therefore, invest time in contractor selection to ensure your project succeeds. Consequently, proper installation delivers the performance and longevity that make spray foam commercial roofing such an excellent investment.

## Frequently Asked Questions About Spray Foam Commercial Roofing

**How much does spray foam commercial roofing cost per square foot?**

Spray foam commercial roofing typically costs $4-10 per square foot installed, depending on foam thickness, coating selection, and roof complexity. However, this investment delivers superior value through energy savings, extended lifespan, and reduced maintenance. Moreover, the system often pays for itself within 5-10 years through lower operating costs. Additionally, many utility companies offer rebates for high-efficiency roofing systems that can offset initial costs.

**Can spray foam be applied over existing commercial roofing?**

Yes, spray foam commercial roofing can often be applied over existing roofing systems, including built-up roofing, single-ply membranes, and metal roofing. However, the existing roof must be structurally sound and free from excessive moisture. Moreover, a professional assessment determines whether restoration is feasible. Furthermore, applying spray foam over existing materials eliminates tear-off costs and reduces project disruption. Consequently, restoration typically costs 40-60% less than complete replacement.

**How long does spray foam commercial roofing last?**

Properly installed and maintained spray foam commercial roofing systems routinely last 50+ years. However, the protective coating requires renewal every 10-20 years to maintain performance. Moreover, this recoating process is straightforward and relatively inexpensive. Therefore, spray foam represents a long-term roofing solution that can literally last the lifetime of your building. Additionally, many spray foam roofs installed in the 1970s continue performing well today after periodic recoating.

**What maintenance does spray foam commercial roofing require?**

Spray foam commercial roofing requires biannual inspections to check coating condition and identify any damage. Moreover, keeping the roof clean and free from debris extends coating life. Additionally, prompt repair of any physical damage prevents moisture infiltration. Furthermore, planning for periodic recoating based on coating condition rather than waiting for failure optimizes performance. Consequently, proactive maintenance maximizes your roofing investment while minimizing long-term costs.

**Is spray foam roofing environmentally friendly?**

Yes, spray foam commercial roofing offers significant environmental benefits. First, exceptional energy efficiency reduces building carbon emissions substantially. Moreover, the long lifespan and restoration capability minimize construction waste. Additionally, modern formulations use environmentally responsible materials and blowing agents. Furthermore, spray foam application requires no water, unlike many roofing processes. Therefore, choosing spray foam supports sustainability goals while delivering superior building performance. Please check out our site for all of your spary foam needs click here