When it comes to protecting your commercial property investment, your roofing choice makes all the difference. Moreover, spray foam commercial roofing has emerged as a game-changing solution for businesses seeking durability, energy efficiency, and long-term value. This comprehensive guide explores the top five reasons why property owners across the United States—from commercial spray foam roofing in Sparta, WI, to commercial spray foam roofing in Redding—are making the switch to this innovative roofing system.

Table of Contents

Toggle1. Unmatched Energy Efficiency and Insulation Performance

The primary advantage of spray foam commercial roofing lies in its exceptional insulation capabilities. Specifically, spray polyurethane foam (SPF) provides an impressive R-value of 6 to 7 per inch of thickness. Consequently, it significantly outperforms traditional roofing materials. This superior thermal resistance creates a continuous insulation barrier that drastically reduces heat transfer between your building’s interior and the outside environment.

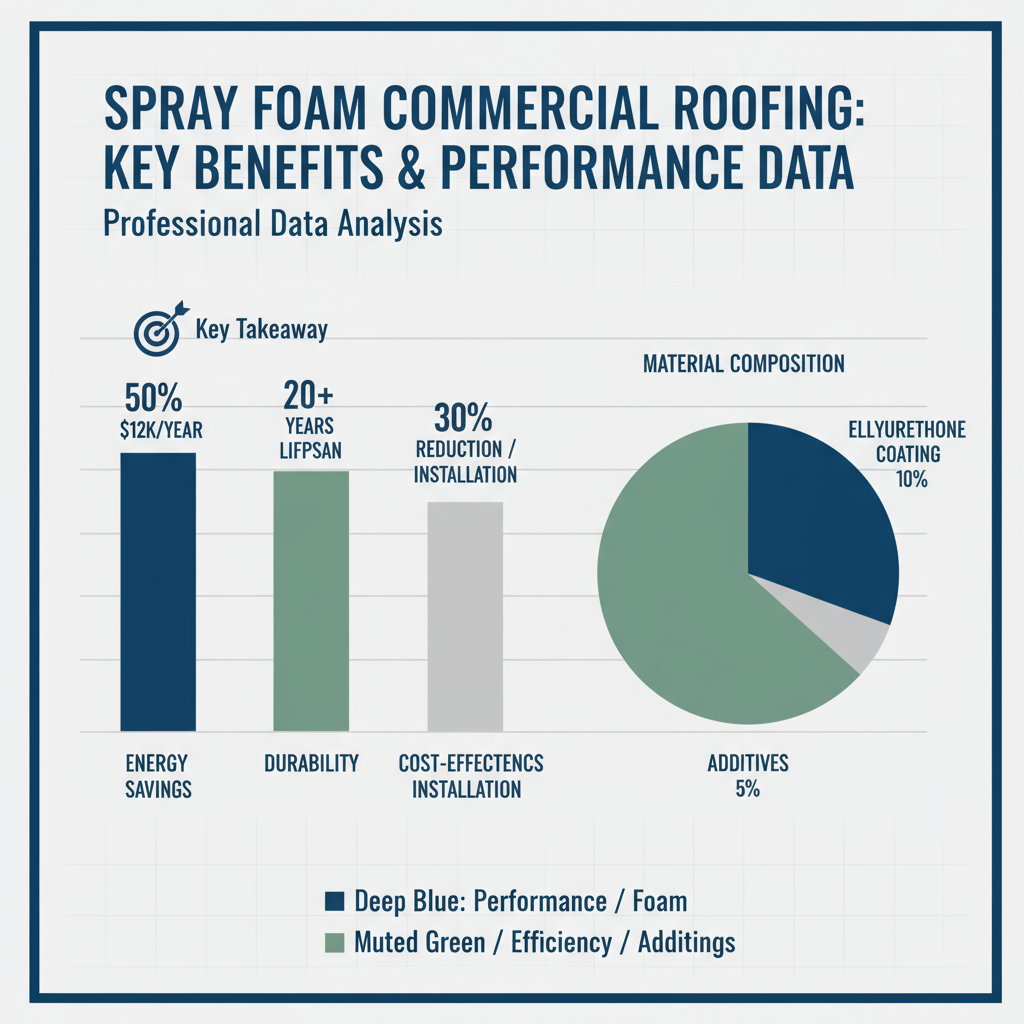

Real-world energy savings are substantial. In fact, commercial property owners typically report energy cost reductions of 30% to 50% after installing spray foam roofing systems. For a 50,000 square foot warehouse, this translates to annual savings of $15,000 to $25,000 or more. Additionally, the foam’s closed-cell structure eliminates thermal bridging—a common problem with metal roofs. Therefore, spray foam under metal roofing has become an increasingly popular retrofit solution.

The Science Behind the Savings

Notably, spray foam roofing works by expanding up to 30 times its liquid volume upon application. As a result, it fills every crack, gap, and irregular surface. This expansion creates an airtight seal that prevents conditioned air from escaping. Furthermore, unlike traditional insulation materials that can settle or compress over time, spray foam maintains its insulating properties throughout its lifespan. According to the U.S. Department of Energy, proper insulation is one of the most cost-effective ways to reduce energy consumption.

2. Seamless Waterproofing and Superior Weather Protection

Traditional roofing systems have inherent weak points—seams, fasteners, and penetrations where water can infiltrate over time. However, spray foam commercial roofing eliminates these vulnerabilities by creating a monolithic, seamless membrane that adheres directly to the roof substrate. Consequently, this continuous barrier provides superior protection against water infiltration, which the National Roofing Contractors Association identifies as the leading cause of commercial roof failure.

Moreover, the waterproofing capabilities of spray foam extend beyond simple leak prevention. The material’s closed-cell structure means individual foam cells are completely sealed. Therefore, it prevents water absorption even if the protective coating is damaged. This is particularly valuable for flat roofs and low-slope commercial buildings, where water pooling presents a constant challenge. Studies show that spray foam roofing systems can withstand ponding water indefinitely without degradation.

Weather Resistance Across All Climates

From the harsh winters of Sparta, WI, to the intense heat of Redding, CA, spray foam roofing performs exceptionally across diverse climate conditions. In addition, the material resists wind uplift forces exceeding 200 mph when properly installed. This makes it ideal for hurricane-prone and high-wind regions. Furthermore, it withstands extreme temperature fluctuations without cracking or deteriorating—common problems with asphalt-based roofing systems according to industry research.

For businesses dealing with freeze-thaw cycles, spray foam provides critical protection. Specifically, the material’s flexibility allows it to expand and contract with temperature changes. Additionally, spray foam’s light color reflects up to 87% of solar radiation, as documented by the Cool Roof Rating Council. As a result, this reduces thermal shock and extends the life of both the foam and the underlying roof structure.

3. Exceptional Longevity and Durability (30+ Years)

How long does spray foam roofing last? When properly installed and maintained, spray foam commercial roofing systems easily surpass 30 years of service life. Furthermore, many installations last 40-50 years. This longevity dramatically exceeds conventional roofing materials like built-up roofing (15-20 years), EPDM rubber (15-25 years), and even metal roofing (20-30 years without foam insulation).

The secret to this impressive durability lies in the material’s composition and installation method. Specifically, spray polyurethane foam is inherently stable and resistant to degradation from UV exposure when protected by an appropriate elastomeric coating. These coatings, which should be reapplied every 10-15 years, act as a renewable protective layer. Consequently, this maintenance requirement is minimal compared to the complete roof replacements required by other systems.

Cost-Effective Maintenance and Repairability

One frequently asked question is: Can spray foam roofing be repaired? The answer is a resounding yes. Unlike many roofing systems that require extensive tear-offs, spray foam roofs are highly repairable. Therefore, small punctures, cracks, or coating failures can be easily addressed. This repairability significantly reduces long-term maintenance costs.

Furthermore, routine maintenance for spray foam roofing is straightforward and affordable. Annual or bi-annual inspections by qualified spray foam roofing contractors near me ensure early detection of any issues. These inspections typically include checking the coating integrity, clearing drains, and addressing any mechanical damage. As a result, proactive maintenance can extend the system’s life well beyond the initial 30-year expectation.

4. Versatility for Multiple Roof Types and Retrofit Applications

Spray foam commercial roofing’s versatility makes it suitable for virtually any commercial building configuration. Whether you’re working with flat roofs, low-slope roofs, curved surfaces, or irregular geometries, spray foam conforms perfectly to the substrate. Therefore, this adaptability is particularly valuable for older buildings with unique architectural features.

Spray foam metal roof applications represent one of the fastest-growing segments in commercial roofing. Metal roofs, while durable, often suffer from condensation issues, thermal inefficiency, and noise problems. However, applying spray foam under metal roofing or directly over existing metal panels transforms these structures into high-performance building envelopes. Consequently, the foam eliminates condensation by raising the metal temperature above the dew point.

Retrofit and Restoration Advantages

One of spray foam’s most compelling features is its ability to be installed over most existing roofing systems without a complete tear-off. As a result, this capability saves substantial labor costs and reduces waste sent to landfills. According to the EPA, minimizing construction waste is crucial for environmental sustainability. Furthermore, the foam essentially “restores” aging roofs by adding a new protective layer while simultaneously upgrading insulation performance.

For businesses operating in industrial parks, warehouses, and manufacturing facilities, spray foam roofing details include the ability to address complex penetrations seamlessly. The material’s liquid application allows it to flow around these obstacles and create a continuous seal. Therefore, this is something nearly impossible with rigid insulation boards or membrane systems.

Applications Across Building Types

- Warehouses and Distribution Centers: Maximize energy efficiency in large, open spaces

- Manufacturing Facilities: Provide climate control for sensitive processes

- Retail Buildings: Reduce HVAC costs while maintaining customer comfort

- Office Buildings: Improve working environment and reduce operational expenses

- Cold Storage Facilities: Essential for maintaining consistent temperatures

- Schools and Institutions: Long-term durability with minimal maintenance

5. Environmental Sustainability and Building Code Compliance

As businesses increasingly prioritize environmental responsibility, spray foam commercial roofing aligns perfectly with green building initiatives. Specifically, the system’s energy efficiency directly reduces a building’s carbon footprint by lowering heating and cooling demands. Over a 30-year lifespan, a typical commercial spray foam roof can prevent hundreds of tons of CO2 emissions compared to conventional systems.

Moreover, the installation process itself is more environmentally friendly than traditional roofing methods. Since spray foam can be applied over existing roofs, it eliminates the need to tear off and dispose of old roofing materials. Additionally, spray foam roofing manufacturers have made significant strides in developing more environmentally friendly formulations, including bio-based foams that incorporate renewable resources as noted by GSA sustainability guidelines.

Contribution to Global Standards and Certifications

Global commercial spray foam roofing standards continue to evolve, with increasing adoption worldwide due to the material’s performance benefits. In the United States, spray foam roofing systems can contribute significantly to LEED certification through multiple credit categories. These include energy performance, sustainable sites, and innovation in design.

Furthermore, building codes increasingly favor high-performance roofing systems, and spray foam meets or exceeds most requirements. The material achieves high fire ratings when properly coated (Class A fire rating is attainable). Additionally, it meets wind uplift requirements and complies with energy codes in all climate zones according to International Code Council standards. Therefore, working with certified spray foam roofing contractors near me ensures your installation meets all local building codes.

Quality Materials Make the Difference

The performance of any spray foam roofing system depends heavily on using quality materials from reputable spray foam roofing manufacturers. Leading manufacturers invest in research and development to improve foam formulations and develop advanced coatings. Consequently, when selecting a contractor, verify they use materials from established manufacturers with proven track records and comprehensive warranty programs.

Frequently Asked Questions About Spray Foam Commercial Roofing

Spray foam commercial roofing typically costs between $4 and $10 per square foot, depending on factors such as roof complexity and accessibility. While the initial investment is higher than some traditional systems, the energy savings and longevity provide excellent ROI. In fact, payback typically occurs within 5-7 years.

The primary disadvantages include higher upfront costs compared to some alternatives. Additionally, the material requires sensitivity to proper installation techniques and periodic recoating (every 10-15 years). However, these limitations are manageable with proper contractor selection and routine maintenance. Furthermore, the material requires specific weather conditions during installation (temperatures above 40°F and low humidity).

Installation time varies based on roof size and complexity. However, most commercial projects can be completed in 1-5 days. For example, a typical 20,000 square foot roof might take 2-3 days. Consequently, the quick installation minimizes business disruption compared to traditional roofing methods that may take weeks.

Yes, this is one of spray foam’s greatest advantages. The material can be applied over most existing commercial roofing systems. Therefore, this eliminates costly tear-off expenses and reduces waste. However, the existing roof must be structurally sound, dry, and properly prepared before foam application.

Absolutely. Spray foam is actually ideal for flat and low-slope roofs where water drainage is a primary concern. The seamless, monolithic application eliminates seams where water typically infiltrates. Moreover, the material’s closed-cell structure resists water absorption. As a result, it can create positive drainage slopes to eliminate ponding water—a common problem with flat roofs.

Making the Smart Choice for Your Commercial Property

Spray foam commercial roofing represents a paradigm shift in how we protect and optimize commercial buildings. Indeed, the combination of exceptional energy efficiency, seamless waterproofing, remarkable longevity, unmatched versatility, and environmental sustainability makes it a superior choice for property owners seeking long-term value.

While the initial investment may be higher than traditional roofing systems, the total cost of ownership over the roof’s 30-50 year lifespan is significantly lower. Specifically, when you factor in energy savings, reduced maintenance costs, and the avoided expense of multiple roof replacements, the value becomes clear. For businesses in competitive markets, the operational savings and improved building performance provide a genuine competitive advantage.

Whether you’re managing properties in Sparta, WI, Redding, CA, or anywhere in between, spray foam commercial roofing offers a proven solution backed by decades of successful installations. Therefore, the key to achieving optimal results lies in partnering with experienced, certified spray foam roofing contractors who understand the nuances of proper installation and can recommend the right system for your specific building and climate. For more information on commercial roofing best practices, consult industry resources and professional associations.