Last Updated: October 15, 2025

Your commercial roof is one of your most important investments. When a roof deteriorates, property managers must choose: pay for expensive tear-off and replacement, or choose a new restoration solution?

Spray foam restoration is a game-changing alternative to replacement. It extends your roof’s life, improves its performance, and saves you money, all without the disruption of a full replacement.

This guide covers everything about spray polyurethane foam (SPF) roof restoration. It explains the process and the long-term benefits to help you make an informed decision about your roofing investment.

What is Spray Foam Roof Restoration?

Spray foam restoration is an advanced technique. It involves applying spray polyurethane foam (SPF) directly over an existing commercial roof. Unlike traditional roof replacement that requires complete tear-off and disposal of old materials, this method creates a smooth, complete membrane. This membrane renews aging roofs while adding superior insulation and waterproofing.

The process transforms deteriorating roofs into high-performance systems. It addresses multiple issues at once: eliminating leaks, improving energy efficiency, and extending service life by decades. This new approach has gained widespread use across commercial, industrial, and institutional buildings seeking sustainable, cost-effective roofing solutions.

The Components of a Spray Foam Roof System

A professional spray foam roof system has three essential layers that work together to protect your building:

Base Preparation Layer: Workers thoroughly clean and prepare the existing roof surface. They remove debris, moisture, and contaminants. Workers repair any damaged sections to ensure proper foam adhesion and system integrity.

SPF Application Layer: Technicians spray liquid polyurethane foam that expands and hardens into a rigid insulation layer. This smooth membrane fits roof contours, penetrations, and irregular surfaces. It provides exceptional R-values ranging from R-6 to R-7 per inch of thickness.

Protective Coating System: A specialized coating protects the foam from UV radiation, physical damage, and environmental exposure. This coating determines the system’s longevity. It typically requires recoating every 15-20 years to maintain optimal performance.

How It Differs From a Full Replacement

Traditional roof replacement follows a destructive process. Crews tear off existing materials. They expose the building interior to weather risks. They generate substantial waste and install entirely new roofing systems. This approach costs more, takes longer, and disrupts normal operations significantly.

Spray foam roof repair and restoration offer compelling advantages. The existing roof remains in place, serving as the base for the new SPF system. This eliminates disposal costs, reduces labor expenses, and minimizes business interruption. Installation typically completes in days rather than weeks. The building remains protected throughout the process.

The restoration approach works particularly well for built-up roofs, modified bitumen systems, single-ply membranes, and metal roofing. These roofs must have moderate deterioration but structurally sound decking.

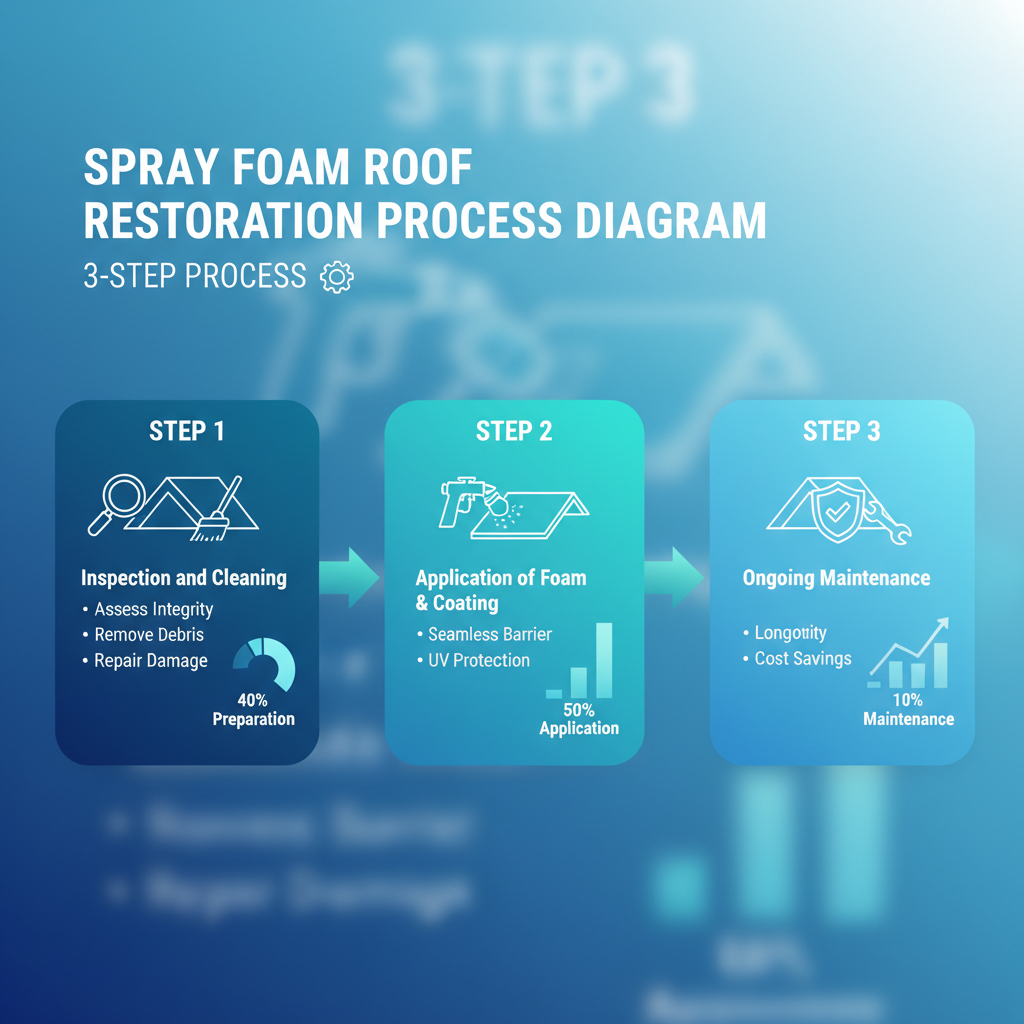

The Spray Foam Roof Restoration Process: Step-by-Step

Understanding the restoration process helps property managers set realistic expectations and ensure quality work. Professional contractors follow systematic procedures to deliver long-lasting results.

Step 1: Inspection and Cleaning

Every successful restoration begins with a comprehensive roof inspection. Certified technicians assess structural integrity. They identify moisture intrusion. They evaluate existing membrane condition and document areas requiring repair. This diagnostic phase determines whether your roof qualifies for restoration or needs replacement.

Once approved, crews thoroughly clean the entire roof surface. They use power washing and industrial cleaning equipment. Removing dirt, biological growth, loose granules, and contaminants ensures optimal foam adhesion. Workers must eliminate any standing water. The roof must achieve proper dryness before proceeding.

Damaged sections receive targeted repairs. Technicians replace saturated insulation. They fix structural issues. They seal penetrations and address any conditions that could compromise the new SPF system. This preparation phase proves critical for long-term performance.

Step 2: Application and Curing

Professional applicators use specialized spray equipment. They apply expanding foam in controlled passes across the roof surface. The liquid components mix at the spray gun nozzle. This triggers a chemical reaction that causes rapid expansion and hardening.

Application typically occurs in multiple passes. Workers build up thickness gradually to achieve specified R-values and proper slope adjustments. Technicians carefully manage thickness variations. They ensure adequate coverage around penetrations, edges, and transitions. Proper technique prevents common issues like over-spraying, uneven thickness, and inadequate density.

The foam begins curing immediately upon application. It reaches sufficient hardness for foot traffic within minutes. However, complete curing requires 24-48 hours before applying protective coatings. Weather conditions significantly impact application timing. Contractors avoid installation during precipitation, high humidity, or extreme temperatures.

Step 3: The Final Protective Coating

After the SPF fully cures, crews apply multiple coats of coating. This protects against UV degradation, physical abuse, and environmental exposure. This coating system determines the roof’s appearance and longevity.

Most specifications require minimum coating thickness of 20-30 mils applied in two or more coats. The coating embeds granules for enhanced durability and reflectivity. It creates a bright white surface that reflects solar heat and reduces cooling costs.

Quality contractors embed fabric reinforcement at critical areas. These include penetrations, transitions, and high-traffic zones. This reinforcement prevents coating failure and extends system life. Final inspection verifies proper coverage, thickness, and overall system integrity.

Cost of Spray Foam Roof Restoration

Budget considerations drive many roofing decisions. Understanding spray foam roof repair cost factors helps property managers evaluate return on investment and compare alternatives effectively.

Factors That Influence the Final Cost

Spray foam roof restoration costs typically range from $4.00 to $7.00 per square foot. However, several variables affect final pricing:

Roof Size and Complexity: Larger roofs benefit from economies of scale, reducing per-square-foot costs. However, complex roofs with multiple penetrations, varying elevations, and irregular shapes require additional labor and materials. This increases expenses.

Existing Condition: Roofs requiring extensive repairs before foam application cost more than those needing minimal preparation. Moisture damage, structural issues, and deteriorated substrates require fixing before restoration can proceed.

Foam Thickness: Required R-value specifications determine foam thickness. Building codes, climate zones, and energy efficiency goals influence this decision. Each additional inch adds approximately $0.50-$1.00 per square foot.

Coating System: Premium coating systems with higher solids content, enhanced durability, and extended warranties cost more upfront. However, they deliver superior long-term value.

Location and Accessibility: Geographic location affects material availability and labor rates. Additionally, roofs requiring special access equipment, safety systems, or extended mobilization increase project costs.

Is Spray Foam Roof Restoration Worth the Cost?

When evaluating spray foam roof restoration cost against complete replacement, the value proposition becomes compelling. Traditional tear-off and replacement typically costs $8.00-$15.00 per square foot. This is nearly double the restoration investment.

Beyond initial cost savings, spray foam restoration delivers:

Extended Service Life: Properly maintained SPF roofs last 30-50 years. This matches or exceeds traditional roofing system lifespans while requiring only periodic recoating.

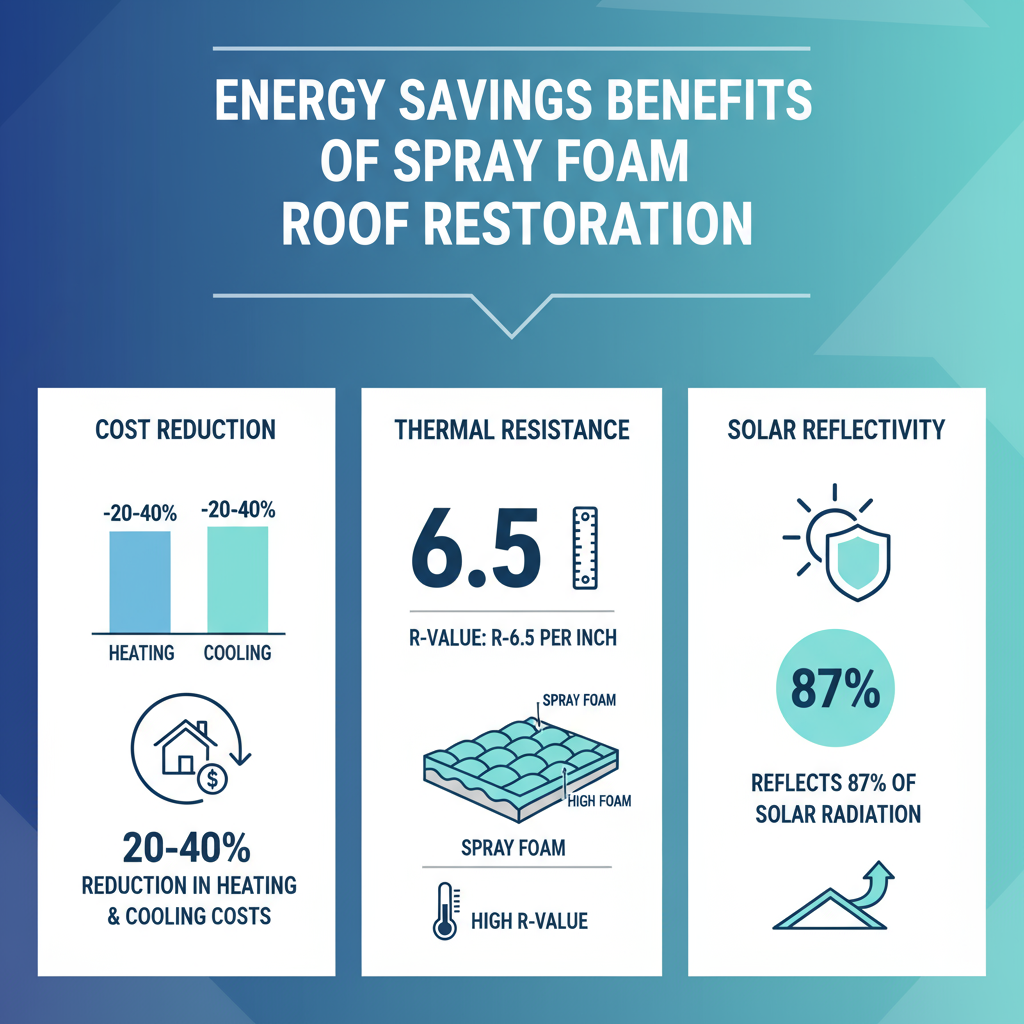

Energy Savings: Superior insulation reduces HVAC loads significantly. Many facilities report 20-40% reductions in heating and cooling costs. These ongoing operational savings offset initial investment within 5-10 years.

Avoided Replacement Costs: Restoration delays expensive tear-off and replacement by 20-30 years. This allows property managers to allocate capital to other priorities.

Tax Benefits: SPF restoration often qualifies for accelerated depreciation and energy efficiency incentives, improving financial returns.

Reduced Downtime: Unlike disruptive tear-off projects, restoration minimizes operational interruption. This avoids revenue loss and productivity impacts.

Benefits of Choosing Spray Foam Restoration

Property managers choosing foam roof repair gain advantages beyond cost savings. This technology addresses multiple performance areas at once.

Long-Term Performance and ROI

Spray foam creates a smooth, complete membrane without seams, fasteners, or weak joints where traditional roofs typically fail. This continuous barrier eliminates common leak pathways. It dramatically reduces maintenance calls and emergency repairs.

The closed-cell foam structure resists moisture absorption. This prevents insulation degradation and maintains thermal performance throughout its service life. Unlike traditional insulation that loses R-value when wet, SPF maintains effectiveness even if minor moisture intrusion occurs.

Wind uplift resistance exceeds that of mechanically-attached systems. The foam adheres completely to the substrate. This creates full attachment across the entire roof area. This continuous bond withstands severe weather events better than traditional systems relying on fasteners or adhesive patterns.

Return on investment calculations consistently favor spray foam restoration. When combining initial cost savings, energy efficiency gains, extended service life, and reduced maintenance expenses, most facilities achieve payback within 5-8 years. They then enjoy benefits for decades.

Minimal Disruption and Sustainability

Traditional tear-off projects generate massive waste streams. A typical 50,000 square foot re-roofing project produces 50-75 tons of debris destined for landfills. Spray foam roof restoration eliminates this waste entirely. It aligns with corporate sustainability goals and LEED certification requirements.

Building occupants continue normal operations throughout restoration. Unlike tear-off projects exposing interior spaces to weather, noise, and debris, spray foam application occurs entirely on the roof surface. Most occupants remain unaware of ongoing work.

Material sustainability extends beyond waste reduction. Modern SPF formulations incorporate recycled content, renewable resources, and low-VOC components. The insulation properties reduce long-term energy consumption. This decreases carbon footprint throughout the building’s operating life.

Many facilities pursue spray foam restoration specifically to meet Environmental Social Governance (ESG) commitments. This demonstrates environmental stewardship while achieving practical roofing solutions.

Enhanced Insulation and Energy Savings

The exceptional R-value of closed-cell spray foam—approximately R-6.5 per inch—exceeds traditional roofing insulation alternatives. This superior thermal performance creates immediate energy savings by reducing heat transfer through the roof assembly.

During summer months, the bright white coating reflects up to 87% of solar radiation. This significantly reduces cooling loads. Combined with foam insulation underneath, this cool roof system can lower surface temperatures by 50-80°F compared to dark conventional roofs.

Winter performance proves equally impressive. The continuous insulation layer eliminates thermal bridges common in board insulation systems. This prevents heat loss and reduces heating costs. Buildings in heating-dominated climates often see the most dramatic energy savings.

Improved building envelope performance extends HVAC equipment life by reducing runtime and thermal cycling. Many facilities report that reduced HVAC maintenance and replacement costs further enhance restoration ROI.

Third-party studies document energy savings ranging from 20-40% following spray foam roof restoration. Payback periods often fall under 10 years even before considering other restoration benefits.

Common Questions About Spray Foam Roofs

Property managers evaluating spray foam technology commonly ask similar questions. Understanding these concerns helps make informed decisions.

How Long Can You Expect a Spray Foam Roof to Last?

A properly installed and maintained spray foam roof system typically lasts 30-50 years or more. This exceptional longevity rivals or exceeds traditional commercial roofing systems while offering superior performance characteristics.

The key to achieving this lifespan lies in regular maintenance and periodic recoating. The protective coating layer shields foam from UV degradation and physical damage. However, it gradually weathers over time. Most manufacturers recommend recoating every 15-20 years to maintain warranty coverage and optimal performance.

Recoating costs substantially less than original installation—typically $1.50-$2.50 per square foot. It essentially resets the roof warranty for another 15-20 years. This renewable characteristic makes spray foam one of the most economical long-term roofing investments available.

Buildings with properly maintained SPF roofs installed in the 1980s continue performing excellently today. This demonstrates the technology’s proven track record. Regular inspections, prompt repairs of physical damage, and timely recoating ensure maximum service life.

The Pros and Cons of a Spray Foam Roof

Like any roofing technology, spray foam offers distinct advantages and considerations:

Advantages:

- Smooth, complete waterproof membrane eliminates leak-prone seams

- Superior insulation reduces energy costs substantially

- Lightweight system adds minimal structural load

- Fits irregular surfaces and penetrations

- Sustainable solution reduces waste and environmental impact

- Quick installation minimizes disruption

- Self-flashing around penetrations and details

- Renewable through periodic recoating

Considerations:

- Requires skilled, certified installers for proper application

- Weather-dependent installation (temperature and moisture restrictions)

- Initial cost higher than some traditional options (though ROI favorable)

- Requires periodic recoating to maintain UV protection

- Physical damage from foot traffic or dropped objects can occur

- Not suitable for roofs with significant structural issues or severe deterioration

- Local code officials may have limited familiarity with technology

Understanding these factors helps set appropriate expectations. Working with experienced contractors and following manufacturer maintenance guidelines maximizes benefits while minimizing potential concerns.

Common Problems and Solutions

Even high-quality spray foam roofs occasionally develop issues requiring attention. Understanding common problems and appropriate responses helps maintain system integrity.

When to Use a DIY Repair Kit

Minor punctures, small damaged areas, and isolated coating failures often permit owner-performed repairs. You can use spray foam roof repair kits available from roofing suppliers. These kits typically include:

- Small quantities of spray foam for filling voids

- Patching fabric or mesh reinforcement

- Coating materials for sealing repairs

- Application tools and instructions

Appropriate DIY repairs include:

- Punctures smaller than 2 inches in diameter

- Isolated coating blisters or peeling under 6 inches

- Minor edge termination repairs

- Small fastener or penetration seal failures

Following manufacturer instructions carefully ensures repairs work properly with the existing system. Clean the damaged area thoroughly. Allow repairs to cure completely. Apply coating protection over repairs.

When to Call a Professional

Certain conditions exceed DIY capabilities and require professional spray foam flat roof repair services:

Extensive Damage: Multiple damaged areas, large punctures, or widespread coating failure indicate systemic issues. These require professional assessment and comprehensive repair strategies.

Moisture Intrusion: Active leaks, saturated insulation, or interior water damage need professional investigation. Professionals identify sources and implement proper fixes before repairing surfaces.

Adhesion Failures: Areas where foam separates from substrate or coating peels from foam require professional re-preparation. They need proper materials to ensure lasting repairs.

Structural Concerns: Sagging areas, visible bending, or damaged decking require structural evaluation. This must happen before proceeding with any roof repairs.

Professional contractors have specialized equipment, manufacturer-approved materials, and technical expertise to address complex problems correctly. Attempting repairs beyond appropriate scope often worsens conditions and voids warranties.

Common Issues and Their Solutions

Blistering: Coating blisters usually result from trapped moisture or application over insufficiently cured foam. Solutions involve cutting out affected areas, allowing proper drying, and reapplying materials correctly.

Ponding Water: While SPF roofs tolerate occasional ponding better than many systems, chronic standing water speeds coating breakdown. Proper solutions add foam to create positive drainage, eliminating low areas.

Physical Damage: Foot traffic, dropped tools, or impact from maintenance activities can damage foam and coating. Repairs involve cleaning damaged areas, filling with foam if necessary, and applying appropriate coating systems.

Coating Breakdown: Over time, UV exposure and weathering thin protective coatings. Regular inspections identify areas requiring attention before foam exposure occurs. Timely recoating prevents more extensive repairs.

Implementing preventive maintenance programs minimizes roof traffic. Schedule regular inspections and address minor issues promptly to prevent most major problems. Many facilities establish service contracts with restoration contractors for ongoing maintenance and warranty preservation.

Finding a Qualified Spray Foam Restoration Contractor

Project success depends heavily on contractor selection. The SPF industry requires specialized training, equipment, and expertise that sets qualified contractors apart from general roofing companies.

What to Look for in a Quality Contractor

Manufacturer Certification: Reputable SPF system manufacturers provide comprehensive contractor training and certification programs. Certified contractors demonstrate technical competency, equipment capability, and commitment to quality standards. Always verify current certification status directly with manufacturers.

Experience and Portfolio: Request project portfolios demonstrating similar scope, size, and building type to your facility. Experienced contractors provide references from comparable projects and discuss specific challenges encountered.

Insurance and Bonding: Verify adequate general liability insurance, workers compensation coverage, and bonding appropriate to project size. Professional contractors maintain proper coverage protecting building owners from liability.

Written Warranties: Quality contractors provide comprehensive warranties covering materials and workmanship. Review warranty terms carefully. Understand coverage duration, exclusions, and maintenance requirements. Many manufacturers offer extended warranties when certified contractors install their systems.

Safety Programs: Professional contractors implement formal safety programs. They conduct regular training and maintain excellent safety records. Request documentation of safety programs and OSHA compliance.

Questions to Ask Before You Hire

Interviewing prospective contractors helps identify the most qualified company:

- How many years have you specialized in spray foam roofing?

- What manufacturer certifications do you currently hold?

- Can you provide references from similar projects completed within the past two years?

- What warranty do you offer, and what does it cover?

- How do you handle weather delays and protect buildings during interruptions?

- What quality control measures do you implement during application?

- Do you employ your own crews or use subcontractors?

- What post-installation inspections and documentation do you provide?

- How do you handle warranty service and future maintenance needs?

- Can you provide detailed specifications and application procedures for my specific roof?

Quality contractors answer these questions thoroughly. They demonstrate technical knowledge and provide comprehensive documentation. Avoid contractors offering suspiciously low bids, lacking manufacturer certifications, or unable to provide verifiable references.

Conclusion

Spray foam roof restoration represents a proven, cost-effective alternative to traditional tear-off and replacement for aging commercial roofs. This advanced technology extends service life, enhances energy efficiency, and delivers substantial cost savings while aligning with sustainability goals.

The smooth, complete SPF membrane eliminates leak pathways common in traditional roofing systems. Superior insulation properties reduce energy consumption dramatically. Many facilities report 20-40% savings on heating and cooling costs. The renewable nature of spray foam systems—through periodic recoating—provides exceptional long-term value. Properly maintained roofs last 30-50 years or more.

When existing roof substrates remain structurally sound despite surface deterioration, spray foam restoration offers compelling advantages. These include lower initial costs, minimal disruption, substantial waste reduction, and immediate performance improvements.

Success requires partnering with qualified, manufacturer-certified contractors. They understand SPF technology details and follow proper application procedures. Take time to select the right contractor. Establish realistic expectations and commit to ongoing maintenance. This ensures your restoration investment delivers decades of reliable service.

If your commercial roof shows age-related deterioration but maintains structural integrity, now represents the ideal time to explore spray foam restoration options. A professional assessment determines whether your facility qualifies for this solution.

Ready to transform your aging roof into a high-performance asset? Contact a certified spray foam roofing contractor today for a comprehensive inspection and customized restoration proposal.Please check out our site for all of your spary foam needs click here

Frequently Asked Questions

Q: How long does a spray foam roof last?

A: A spray foam roof system, when properly installed and maintained, typically lasts 30-50 years or more. The key factor is the protective coating. It requires recoating every 15-20 years to protect the foam from UV radiation and physical damage. This periodic maintenance essentially renews the warranty and extends service life indefinitely.

Q: Is spray foam roof restoration worth it?

A: Yes, for qualifying candidates. When roof decking remains structurally sound and existing roof systems prove suitable for restoration, spray foam offers exceptional value. Projects typically cost 50-70% less than complete tear-off and replacement. They provide superior insulation and eliminate waste. Combined with energy savings of 20-40% and extended service life, most facilities achieve positive ROI within 5-10 years.

Q: How much does spray foam roof restoration cost?

A: Costs vary based on project size, location, existing conditions, and specifications. On average, expect $4.00-$7.00 per square foot for complete spray foam roof restoration. This includes preparation, foam application, and protective coating. This compares favorably to $8.00-$15.00 per square foot for traditional tear-off and replacement. Additional factors influencing cost include foam thickness, coating system selection, and repair requirements.

Q: How long does the restoration process take?

A: One of spray foam restoration’s key advantages is speed. While traditional tear-off and replacement projects require weeks, spray foam restoration typically completes in 2-5 days for average-sized commercial facilities. This minimizes disruption to business operations significantly. Actual duration depends on roof size, complexity, weather conditions, and required preparation work.

Q: Can spray foam be applied over any existing roof?

A: Spray foam works well over most commercial roofing systems. These include built-up roofs, modified bitumen, single-ply membranes (TPO, PVC, EPDM), and metal roofing. However, roof decking must be structurally sound. Existing systems cannot have extensive moisture damage or severe deterioration. Professional inspection determines suitability. Severely degraded roofs, those with major structural problems, or surfaces with extensive moisture saturation typically require replacement rather than restoration.

Latest Roofing Insights

Spray Foam Commercial Roofing: Top 7 Reasons to Choose It in 2025

Discover the top 7 reasons to choose spray foam commercial roofing in 2025. Energy savings,

Spray Foam Commercial Roofing: Top 5 Proven Benefits for 2025

Discover spray foam commercial roofing benefits: 30-50% energy savings, 30+ year lifespan, seamless waterproofing, and

Spray Foam Roof Restoration: The 2025 Property Manager’s Guide

Save 50-75% vs. a full roof replacement! Learn how spray foam roof restoration extends roof